Electronics Manufacturing

The whole thing is more than the sum of its parts. Looking ahead, when it comes to flexible production solutions.

Here you find the important facts and figures about the electronics manufacturing.

Performance spectrum

Production, System Assembly, SMT, THT, Electromechanical Assembly, Test, Ruggedizing, Conformal coating, Underfill, Silicon dispensing, Potting, 3D-Print

Facts and Figures

10 SMT linies

about 6,000 PCBA variants

Ø 150 Mio. assembled components monthly

1 – 50,000 lot size

< 11 min. product setup time

Awards

1st Bavarian Resource Efficiency Prize

Augsburger Future Award 2020

Bavaria’s Best 50

Entrepreneur Of The Future 2024

Certificates

ISO 9001:2015 , EMAS III, DIN EN ISO/IEC 80079-34:2011 Ex Zertifizierung (ATEX), IATF 16949

Supply Chain Management

On course - our breathing supply chain make a difference.

Your advantage: Deliverable through our worldwide network

Our supply chain makes demand fluctuations and allocation situations economically manageable - cost-optimized, fast and flexible.

Worldwide supplier network

Direct sourcing of key components

Automatic material supply

Continuous supplier rating and supplier development

Extensive quality check of delivered goods

Material supply within the production based on the pull principle

Reliable shipment logistics

Prototype production

Fast, flexible and reliable

BMK supports you with specialized prototype processes in material procurement and electronics production.

Fast preparation of offers

Delivery from 7 working days

No non-recurring costs

Various additional services

Sample production

BMK produces near-series samples using a standardized NPI process

NPI- and DFM-Report - We evaluate the serial capability of your samples

Production on series equipment

Serial number traceability

Cost-effective PCB assembly

Various test procedures

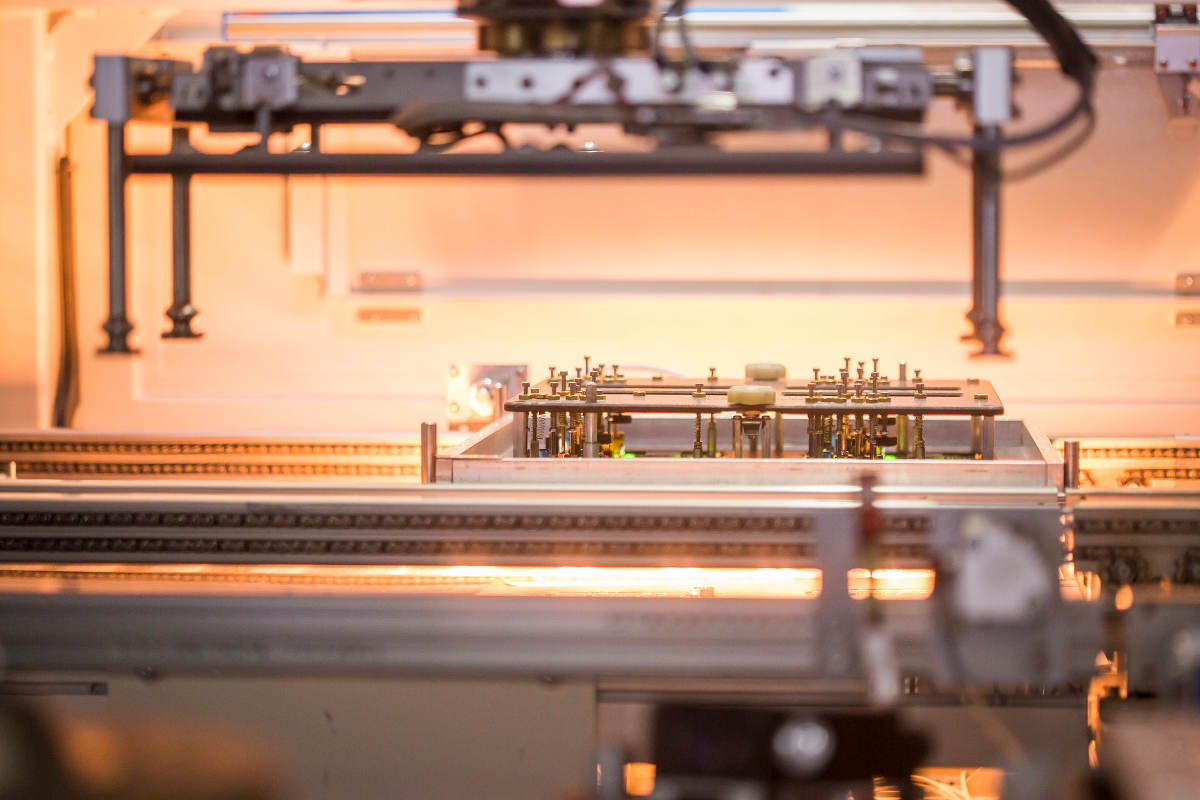

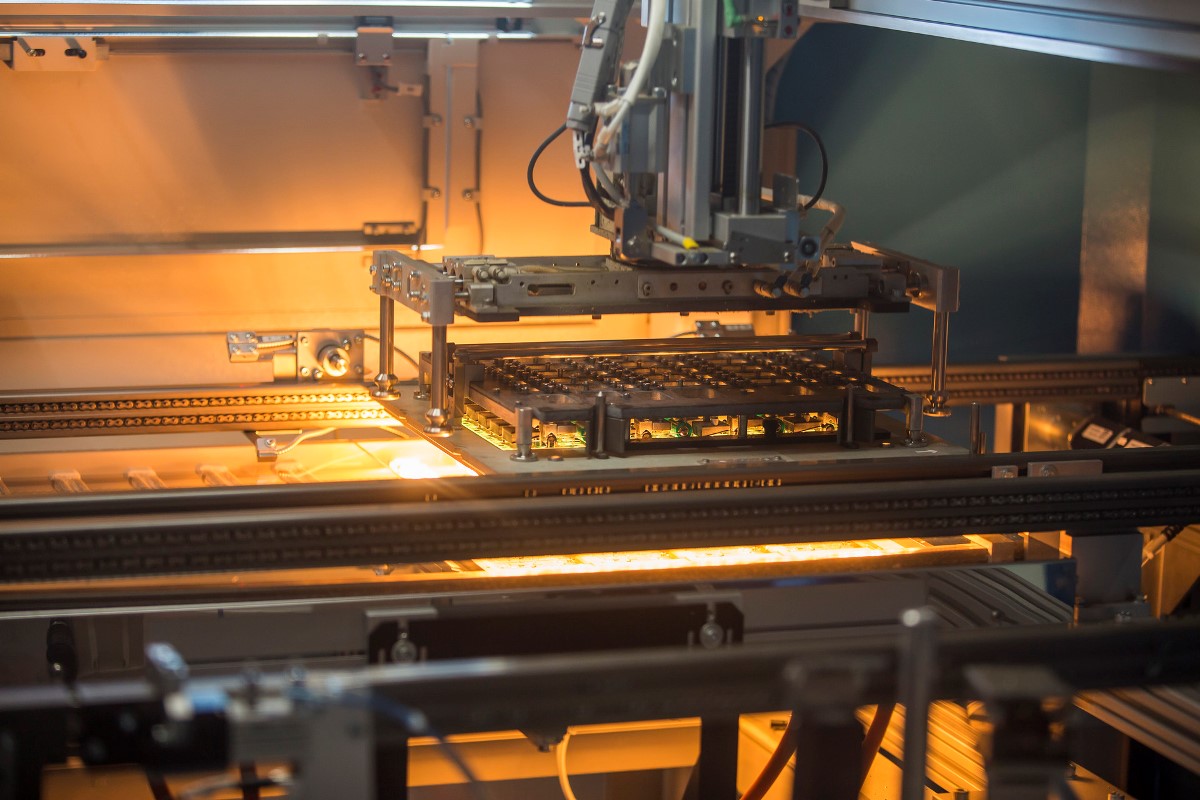

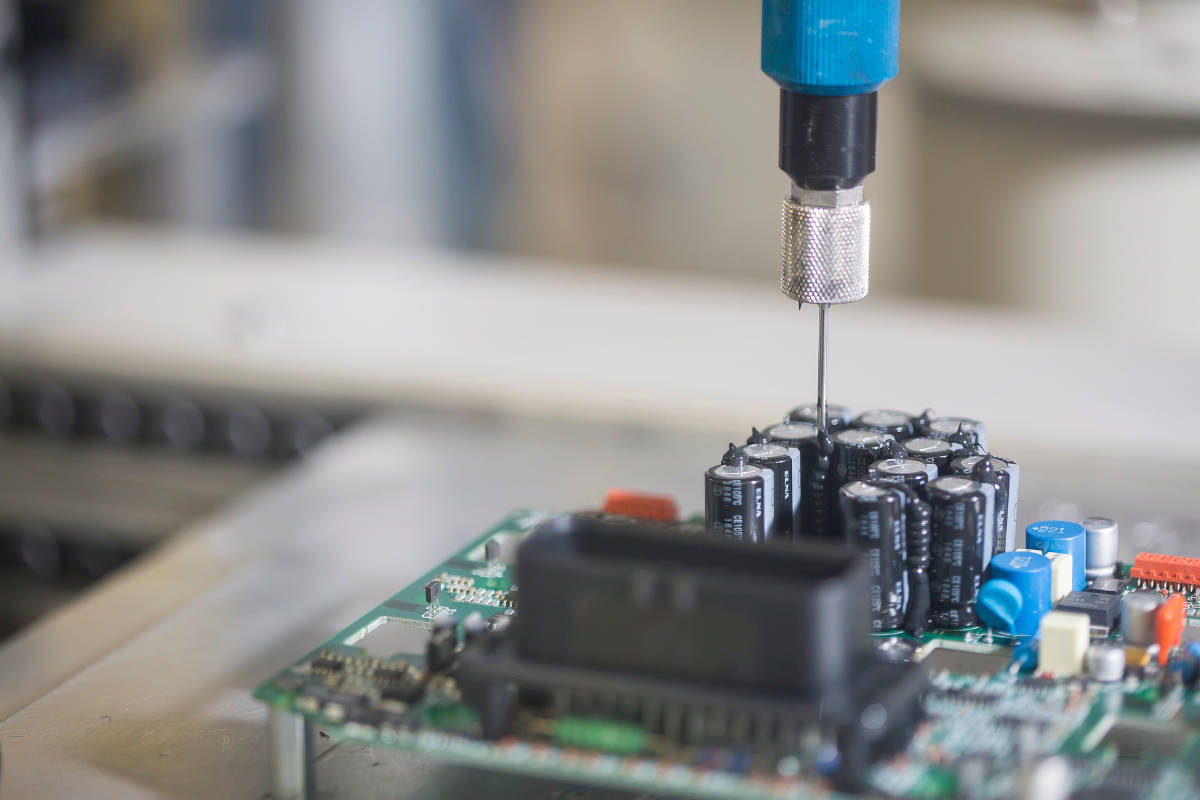

Series production - SMT manufacturing

The series production is known for the consistent implementation of material flow principles and the zero defect strategy. This assures short production times with on time delivery and excellent product quality.

The 10 SMT high performance lines are based on strategic partnerships with our machine supplier. Together we were able to develop solutions for our customer's requirements.

Optical control of the paste printing quality

Sensor based control of the component placement process

Redundant control of the soldering profile

Inline AOI integration

IPC & SPC

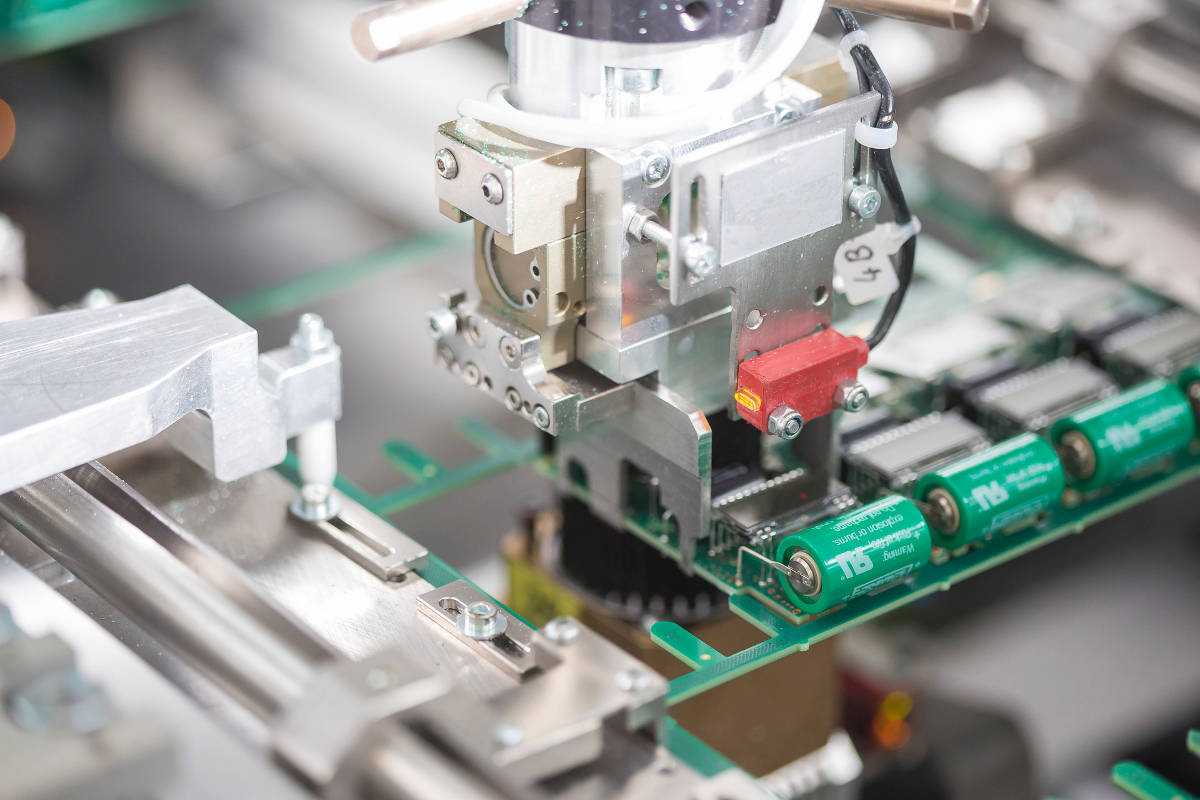

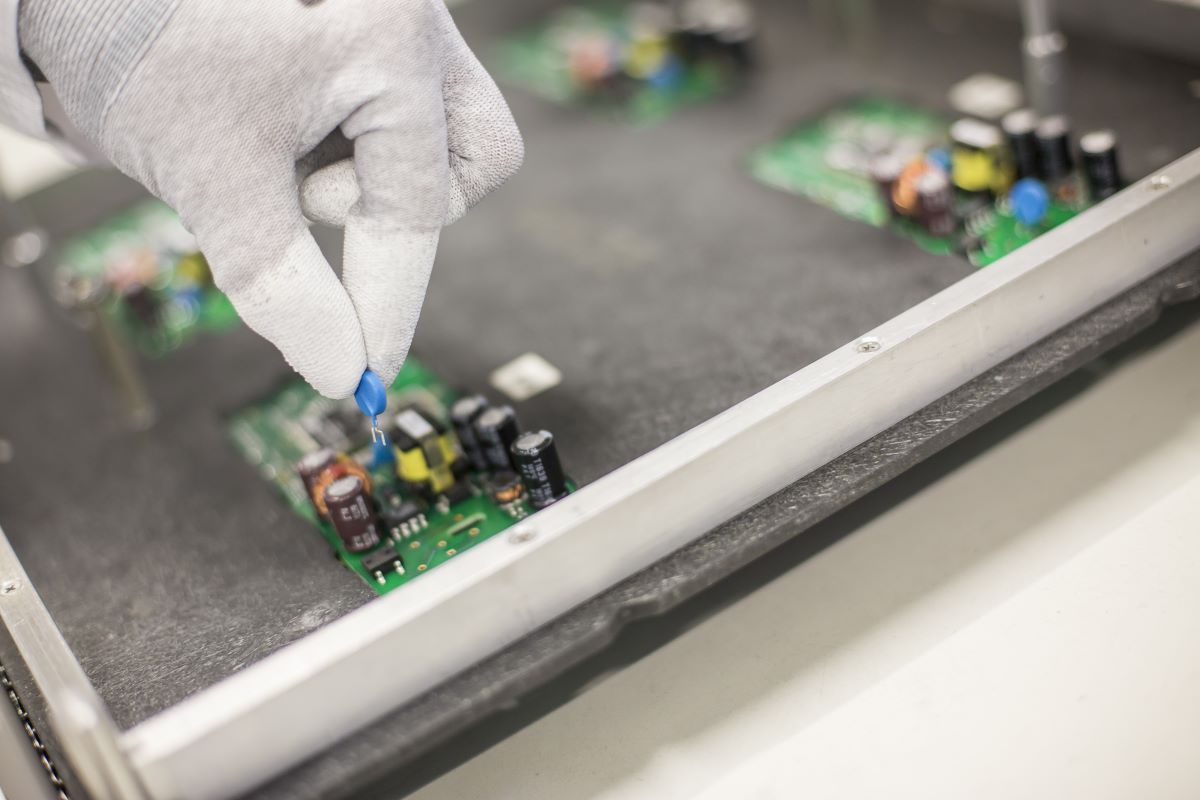

Electromechanical Assembly

The electromechanical assembly is performed in independent production stations. Each of these stations is designed in accordance to the requirements of the application. The pull principle in terms of the material logistics and the parallelization of the production steps ensures an efficient operation.

THT component placement

Wave and selective soldering process (Pb / Pb free)

Press fit technology

Panel separation

Product assembly

Packaging & shipment

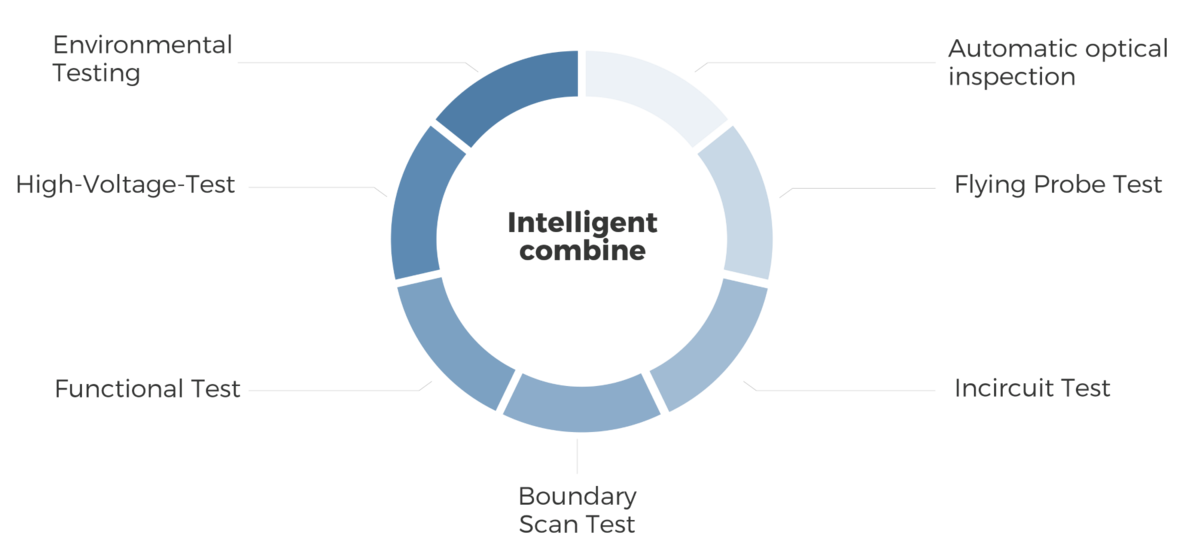

No test - no fun!

The setup is crucial! Innovative and individual: Our test development make a difference.

BMK combines efficient and intelligent testing strategies according to the needs of your product.

Reduce early emergencies

Verification of development

Eliminate component and production errors

Create customer configuration

Fast response time to quality issues

Fulfilment of legal compliance

Risk management / traceability documentation

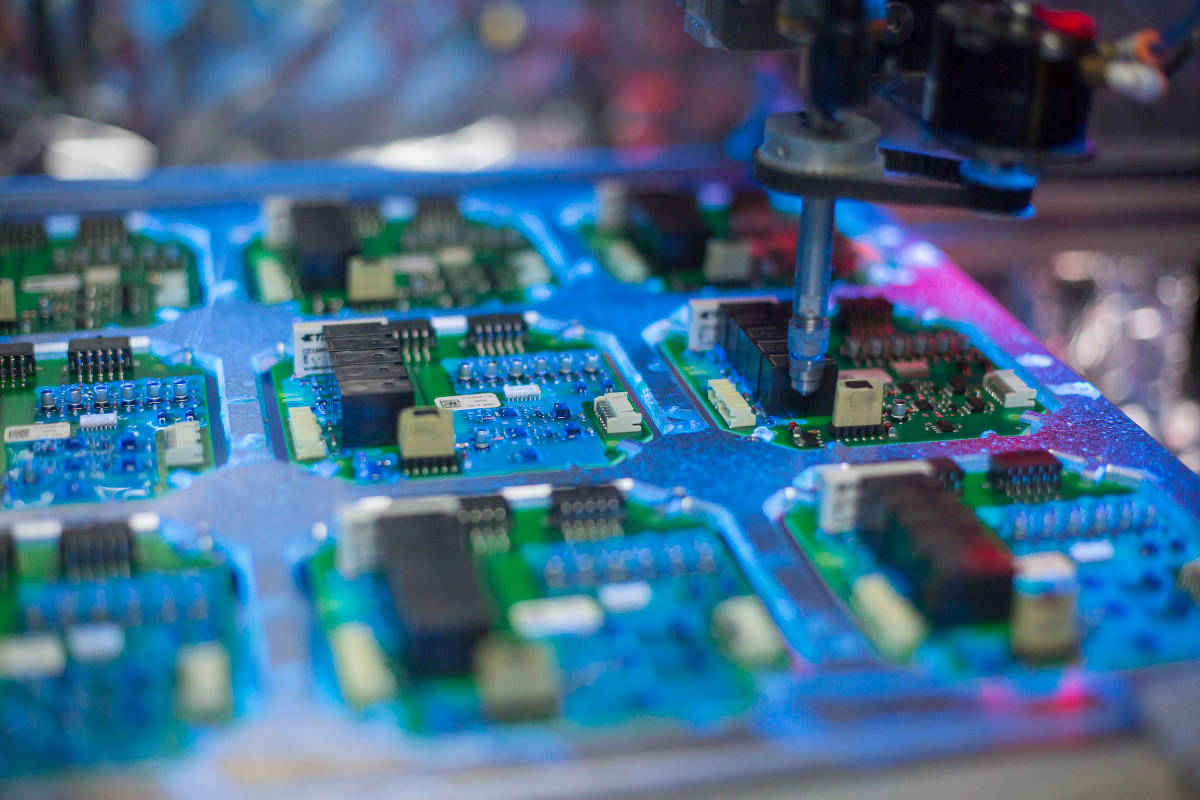

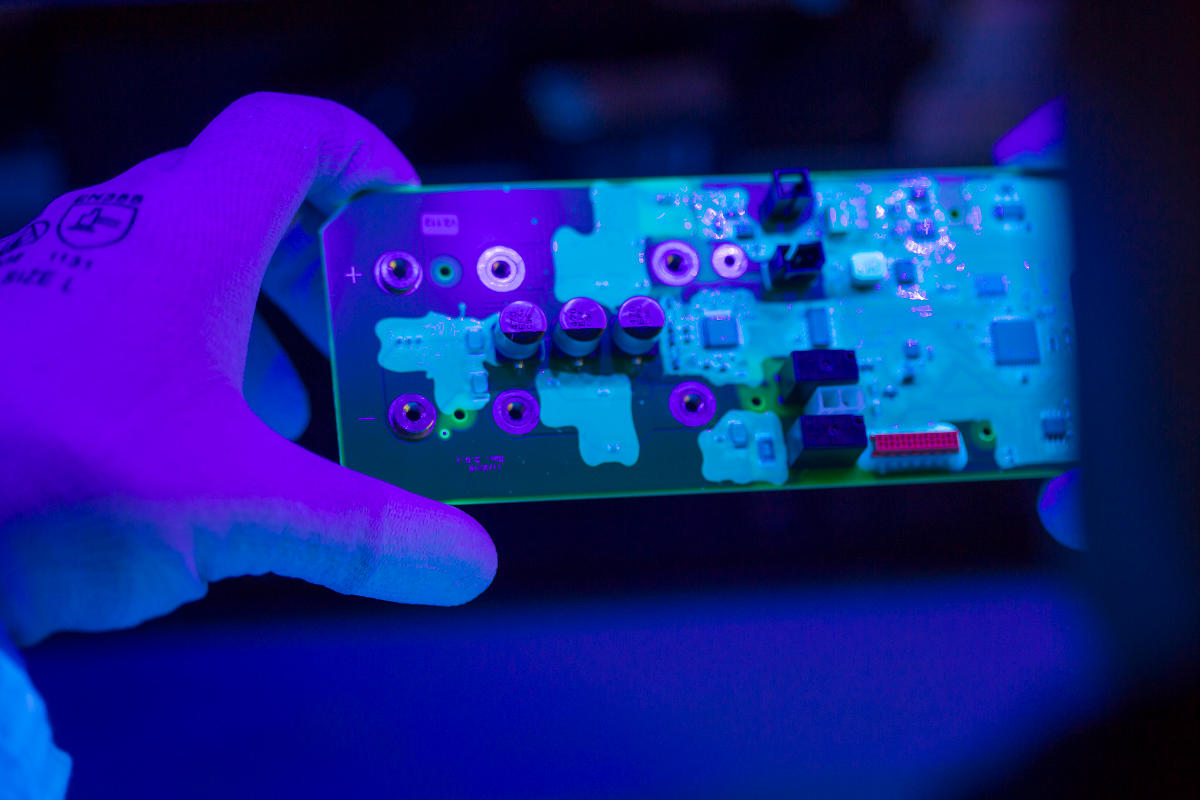

Ruggedizing

Our strategy is to cover all production steps within our facility. Therefore BMK integrated the ruggedizing process of PCBAs inhouse.

Lacquering / Conformal Coating

Underfill

Silicone coating

Potting

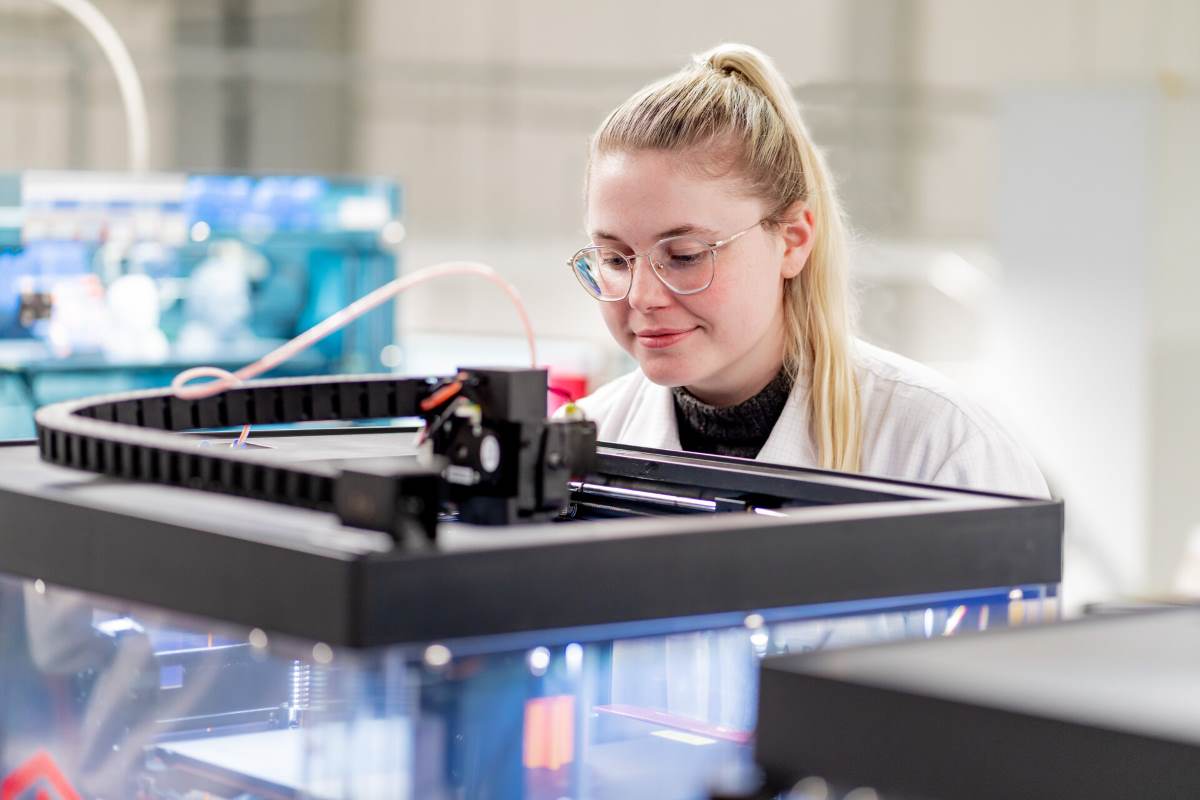

3D Printing

Competently. Flexible. Fast.

Many years of experience in 3D printing makes us a flexible partner in additive manufacturing. Whether housing for prototypes or sample assemblies, we print your desired product quickly and flexibly in our internal machinery with competent support of our experienced employees.

Highlights:

6 machines for 3D printing

Different materials (ESD ,PLA, ABS)

Fast and flexible production

Both great and very fine products

Medium-sized quantities ( <50 )

Contact:

Email: SMT3DDruckshop[at]bmk-electronics.de

Phone: +49 (0) 821 20788-226

Automotive

Now set sails! Ready to go fast with our automotive solutions. The formula for success in your company. Optimal infrastructure and customized automation in the production of your prototypes, series and spare parts. Even in small quantities.

One Stop Shop

Prototypes, series, and spare parts production

Two productions areas just for automotive products

Successful auditing by OEMs and Tier-1

Prototyping on series-based manufacturing lines

Optimized infrastructure

When it gets challenging, we thrive.

When is your BMK moment?